A deep dive into material specs, strength, and common use cases.

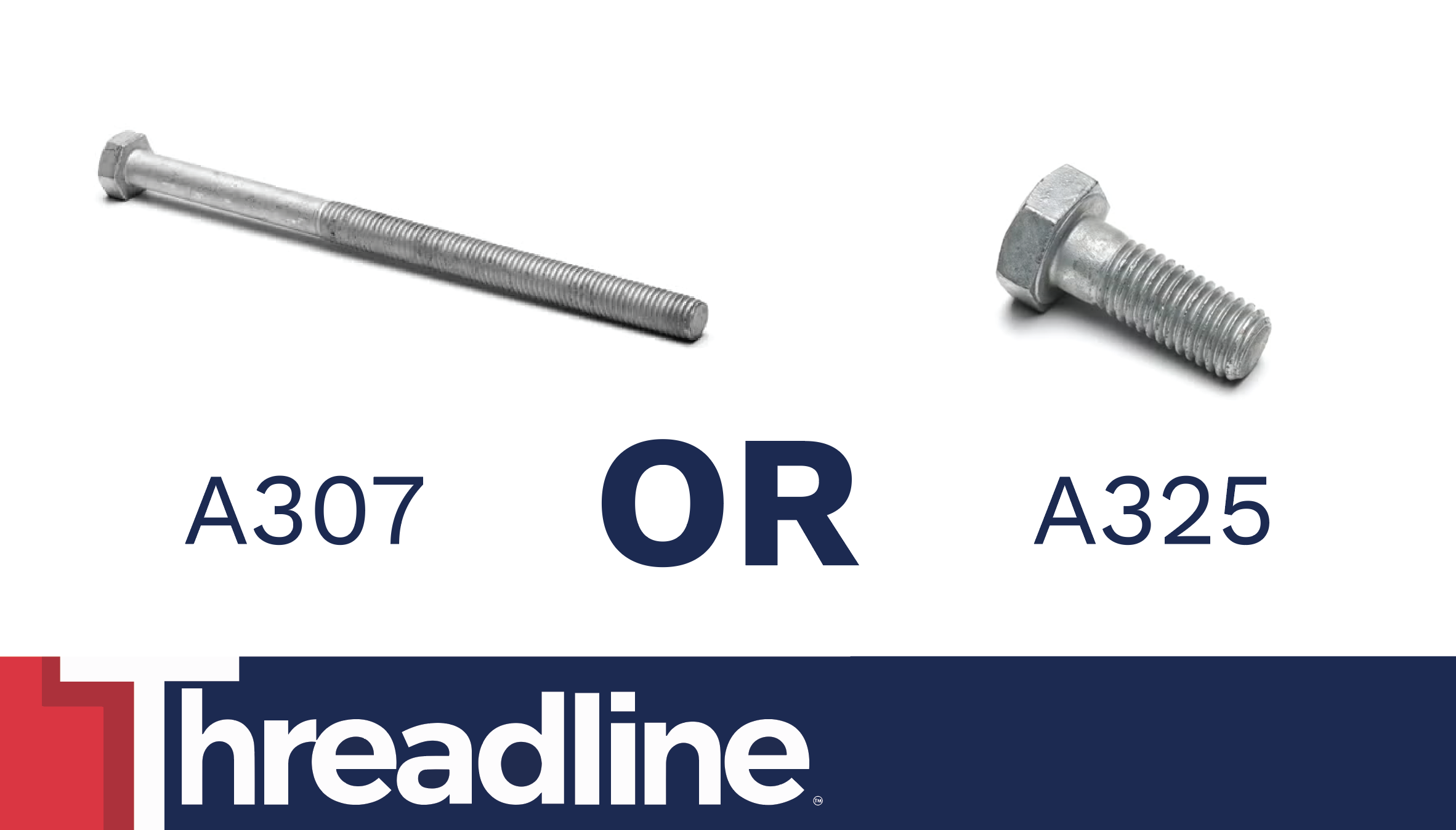

In structural fastening, choosing the right bolt grade is critical to performance, safety, and compliance. Two of the most commonly specified grades in construction and fabrication are A307 and A325 bolts — and while they may appear similar at first glance, they serve very different purposes.

At Threadline, we regularly help customers determine which grade fits their specific needs. Here’s a breakdown of the differences between A307 and A325 bolts to help you make an informed decision.

What Is an A307 Bolt?

ASTM A307 bolts are general-purpose carbon steel fasteners used in non-critical applications. They’re commonly available in two grades:

- Grade A: For general use with cast iron, structural steel, and general construction.

- Grade B: Designed for flanged joints in piping systems (threaded rods, studs, and bolts).

- Tensile Strength: Minimum 60,000 psi

These bolts are not intended for high-strength structural connections and are usually used in low-pressure, static-load environments.

Common Applications:

- Light structural steel framing

- Equipment anchoring

- Low-load support brackets

- General construction fastening

What Is an A325 Bolt?

ASTM A325 bolts are high-strength, heavy hex structural bolts designed specifically for steel-to-steel structural connections. These bolts are quenched and tempered for increased strength and durability.

- Minimum Tensile Strength:

- 105,000 psi (for diameters ≤ 1″)

- 90,000 psi (for diameters > 1″)

Key Characteristics:

- Larger heavy hex head for better load distribution

- Used with hardened washers and nuts

- Typically installed using tensioning methods (e.g., torque wrench or tension control)

Common Applications:

- Steel buildings and bridges

- Structural beam-to-column connections

- Industrial mezzanines and platforms

- Heavy equipment base anchoring

A Quick Comparison

| Feature | A307 Bolt | A325 Bolt |

| Material | Low carbon steel | Medium carbon steel, quenched & tempered |

| Strength | ~60,000 psi tensile | 90,000–105,000 psi tensile |

| Head Style | Standard hex or custom | Heavy hex only |

| Typical Use | Light-duty, non-structural | High-strength structural steel connections |

| Installation Method | Standard torque | Pre-tension or tension control |

| Finish Options | Plain, zinc, HDG | Plain, zinc, HDG (galvanized requires A325 Type 1) |

Which Should You Use?

The choice depends on your load requirements, code compliance, and intended application:

- Use A307 for lighter, static loads where high strength isn’t required — such as anchor bolts, sign supports, or basic construction hardware.

- Use A325 where structural integrity is essential — such as steel frameworks, infrastructure projects, and load-bearing connections that require engineered performance.

If you’re working on a project with DOT, AISC, or building code requirements, chances are you’ll be required to use A325 or another structural-grade bolt.

Threadline: Your Partner for All Bolt Grades

Whether you need A307 bolts for a light-duty project or A325 bolts for critical structural connections, Threadline fabricates and supplies to exact specifications. All of our bolts are made from U.S.-sourced steel and can be finished in plain, hot-dip galvanized, or zinc coatings — depending on the corrosion resistance you need.Need help choosing the right grade for your application? Contact our team for expert advice, quick quotes, and fast turnaround.